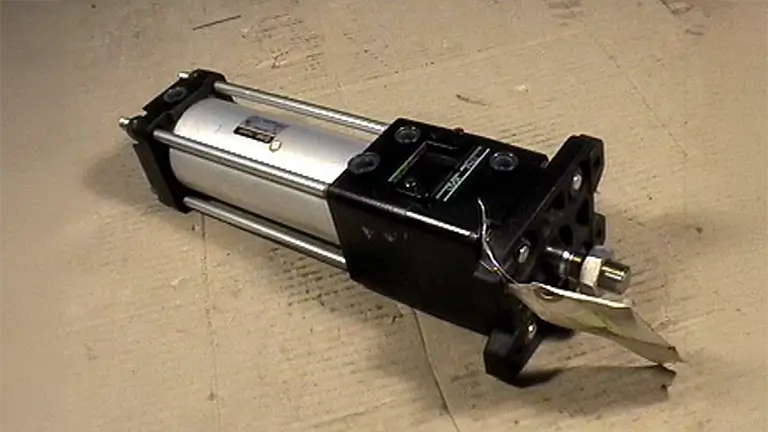

Specialty actuators are devices that create mechanical movement by converting pneumatic, hydraulic, or electric energy. These actuators are used in industrial automation for tasks like moving, gripping, or controlling parts of machines. Many industries where precision and control is needed such as manufacturing, healthcare, and robotics use specialty actuators.

MaximSystems is a top ranked specialty actuators supplier from the leading manufacturers.

Specialty actuators use energy from different sources to create motion. There are several types of actuators, each designed for a specific purpose.

When energy is applied to an actuator, it causes the internal components, like pistons or gears, to move. This movement is then transferred to the machine part or system, allowing it to perform a specific function, such as opening a valve, moving a robotic arm, or lifting a load.

Different types of Specialty Actuators

There are many types of specialty actuators, each with its own unique features and applications:

Certainly! Here are the benefits of using specialty actuators in bullet points:

Choosing the right specialty actuators for your operations might be challenging. Here’s why industries prefer Maxim Systems as a specialty actuators supplier:

Maxim Systems proudly partners with Tolomatic and SMC, two of the leading manufacturers in the specialty actuators industry.

Maxim Systems proudly partners with Tolomatic and SMC, two of the leading manufacturers in the specialty actuators industry.

Specialty actuators are a great device for tasks like handling, moving and gripping. But choosing a specialty actuator is crucial for precise material handling. Choose Maxim Systems as a high quality specialty actuators supplier that enhances your operations.

Maxim Systems is dedicated to offering the finest pneumatic components and related services available.

© Copyright 2023 by Maxim Systems, INC. Designed And Developed By P Cube Digital

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |