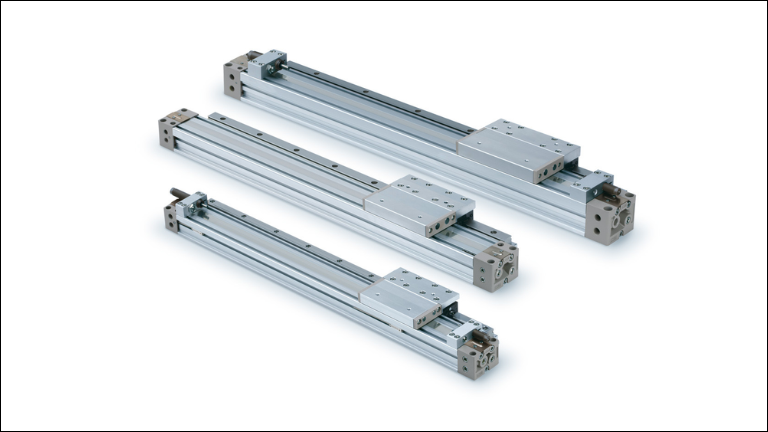

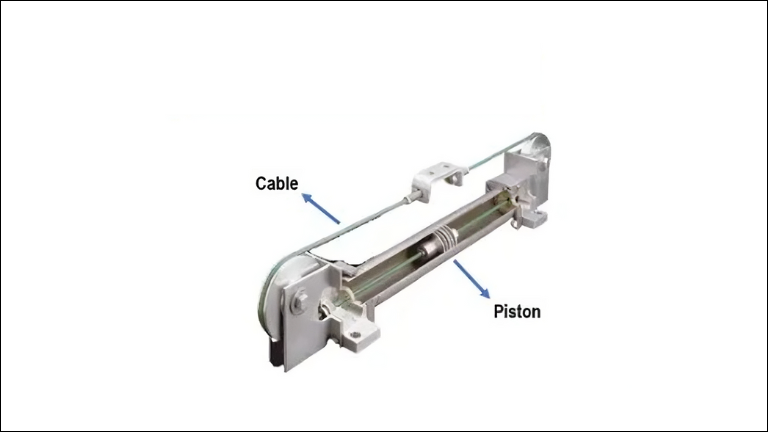

A rodless cylinder uses compressed air to move a load in a straight line. Here’s how it works:

- Air Pressure: Compressed air enters one end of the cylinder, pushing a piston inside.

- Piston Movement: The piston moves along the inside of the cylinder.

- Load Movement: The load is attached to a carriage on the outside of the cylinder. As the piston moves, it pulls or pushes the carriage, moving the load.

- Direction Control: Valves control where the air goes, making the piston and load move back and forth.

This design saves space and can handle heavy loads without bending, making it great for moving and lifting tasks in factories.

How You Can Select a Rodless Cylinder Easily

Selecting a rodless cylinder requires you to consider the following key factors to ensure it meets your needs. Here’s a simple guide to help you choose the right one:

- Load Capacity: Ensure it can handle the maximum load weight.

- Stroke Length: Match or exceed the required travel distance.

- Mounting Space: Fit within the available installation space.

Force - Requirements: Provide the necessary force to move the load.

- Speed: Achieve the desired movement speed.

- Type of Cylinder: Choose based on application needs (Band, Magnetically Coupled, Cable).

- Environmental Factors: Consider temperature, moisture, and chemical exposure.

- Budget: Stay within your budget while meeting requirements.

- Seek Help: Consult Maxim Systems for expert guidance and recommendations.

Industries That Use Rodless Pneumatic Air Cylinders

Rodless pneumatic air cylinders are widely used in various industries and applications due to their efficiency and versatility. Here are some of the key areas where they are commonly employed:

- Material Handling

- Packaging

- Automotive

- Textile Industry

- Printing

- Pharmaceuticals

- Manufacturing

- Food and Beverage

- Robotics

- Warehousing and Logistics

Why Choose Maxim Systems for Rodless Pneumatic Air Cylinders?

Consider Maxim Systems as your provider for rodless pneumatic air cylinders. Here’s what we offer:

Extensive Product Line

We offer a wide range of rodless pneumatic air cylinders to meet various needs and application requirements. You can easily find the right solution for your specific project.

Quality Assurance

Maxim Systems is committed to high-quality products and production techniques, ensuring reliable performance and durability.

Expertise and Knowledge

Our team has the technical knowledge and experience to help you select the best cylinder for your project. We can provide valuable advice and insights.

Competitive Pricing

We strive to offer competitive pricing for our products, making them an affordable option for your budget.

Timely Delivery

Maxim Systems ensures reliable and timely order fulfillment, minimizing delays in your project’s schedule.

Top Manufacturers of Our Rodless Pneumatic Air Cylinders

SMC: SMC Corporation of America, part of a global organization, supports customers in every industrialized country and is the U.S. subsidiary of SMC Corporation based in Japan.

Fabco-Air: For nearly 60 years, Fabco-Air has been a key player in the pneumatics industry, helping customers build top-notch machines. Known for their small pneumatics that deliver high forces, they also manufacture a wide range of high-quality cylinders, valves, sensors, slides, actuators, and other components.

Conclusion: Find the Right Rodless Pneumatic Air Cylinders Supplier with Maxim Systems

Contact us today to learn more about our products and how they can benefit your business. Your success is our main priority, and we are excited to be a part of your journey to greatness.