Linear actuators are the invisible heroes of the industrial world, tirelessly driving automation across countless applications. But even the most robust actuator is rendered useless without a secure and stable mount.

At Maxim Systems, we understand the critical role mounting plays in maximizing performance and longevity. This comprehensive guide delves into everything you need to know about how to mount a linear actuator, from choosing the right method to ensuring optimal installation.

Understanding the Mounting Landscape

The world of actuator mounting offers several methods, each catering to specific needs. Let’s explore the most common options.

Clevis Mounts

These versatile U-shaped brackets reign supreme in popularity, offering simplicity and flexibility. Clevis mounts allow free rotation and pivoting, making them ideal for applications requiring adaptability.

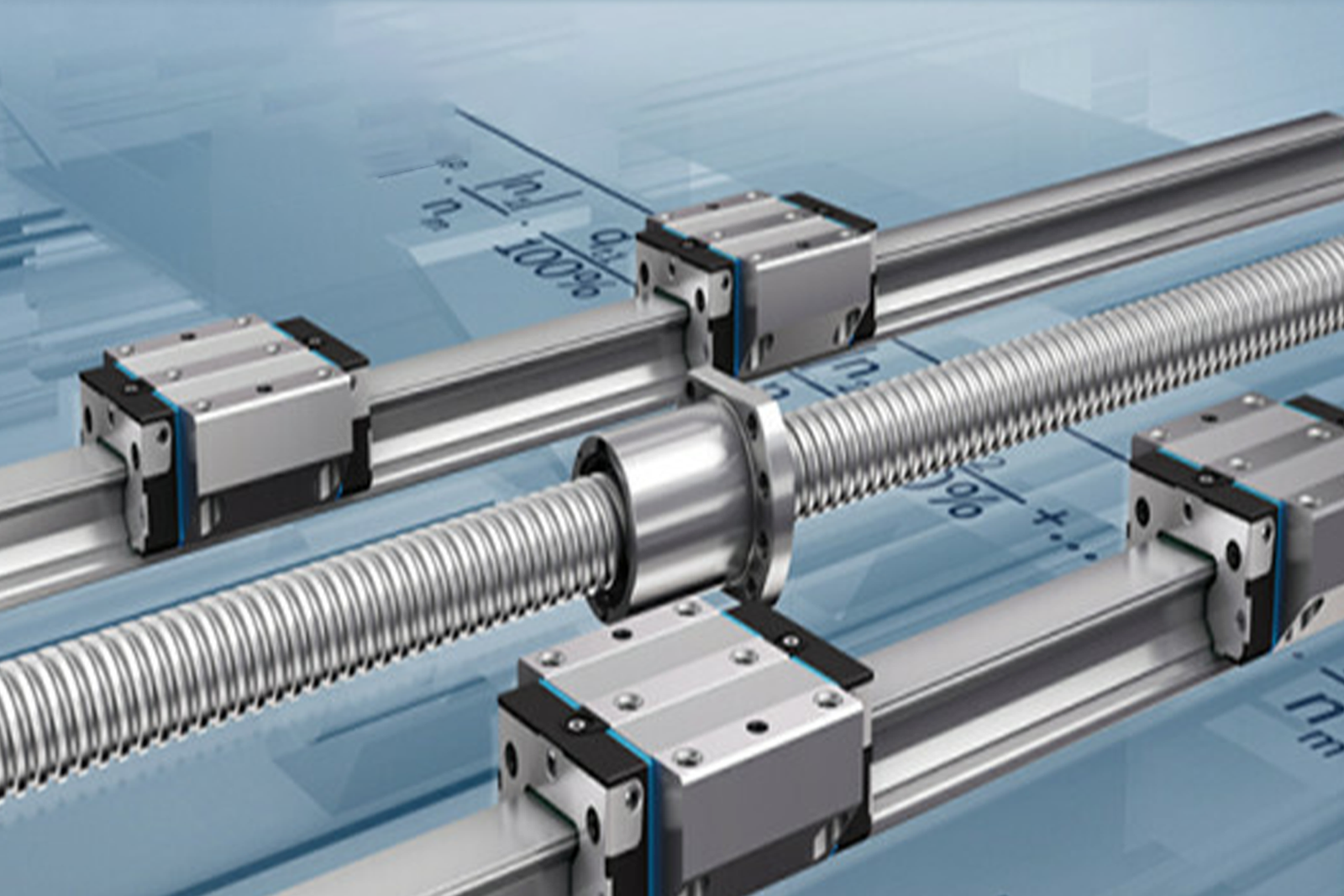

Shaft Mounts

Precision is paramount in applications like CNC machines. That’s where shaft mounts shine. Securing the actuator shaft directly to the surface, they eliminate misalignment concerns, guaranteeing precise linear movement.

Foot Mounts

When heavy-duty applications demand maximum stability, foot mounts rise to the challenge. Bolting directly to the actuator housing, they offer a robust platform for distributing high loads evenly.

Trunnion Mounts

Need the actuator to operate at an angle? Look no further than trunnion mounts. These robust mounts feature two trunnion brackets attaching to the shaft, enabling rotation in one direction.

Custom Mounting Solutions

For unique applications, custom mounting solutions may be the answer. Maxim Systems offers expertise in designing and fabricating bespoke mounts, ensuring your actuator thrives in even the most challenging environments.

Choosing the Perfect Mount

Finding the ideal mounting solution hinges on understanding your application’s specific needs. Here are the key factors to consider:

Load: The weight and force the actuator will encounter.

Stroke: The required distance the actuator needs to travel.

Speed: The desired operating speed of the actuator.

Precision: The demanded level of accuracy for the actuator’s movement.

Environmental Factors: Will the actuator be exposed to dust, moisture, or other harsh conditions?

How to Mount a Linear Actuator: A Step-by-Step Guide

Now that you’ve chosen the perfect mounting method and considered your application’s specific requirements, it’s time to get hands-on and install your linear actuator. Follow these step-by-step instructions for a smooth and successful process:

1. Gather Your Tools and Materials

Linear actuator and mounting brackets: Ensure you have the correct components for your chosen mounting method.

Safety equipment: Wear gloves, safety glasses, and any other necessary protective gear.

Appropriate tools: Depending on your mounting method, you might need wrenches, screwdrivers, a drill, and other tools.

Leveling tool: A spirit level helps ensure precise alignment for optimal performance.

Marking tools: A marker or pen helps mark mounting points and ensure accuracy.

2. Prepare the Mounting Surface

- Choose a stable and sturdy surface that can withstand the anticipated load and vibrations.

- Clean the surface thoroughly to remove any dirt, debris, or grease that could affect adhesion.

- If necessary, use a drill and appropriate drill bits to create mounting holes according to your chosen bracket and mounting method.

- Double-check the alignment of the holes using your leveling tool.

3. Attach the Mounting Brackets

Align the mounting brackets with the pre-drilled holes or designated mounting points on the actuator. Secure the brackets using the appropriate bolts, screws, and washers. Ensure they are tightened to the manufacturer’s recommended torque specifications.

For clevis mounts, insert the clevis pin through the holes on the actuator and the bracket, securing it with a cotter pin or retaining clip.

4. Position the Actuator

Carefully lift the actuator and position it within the mounting brackets. Ensure proper alignment of the shaft or mounting points. Make any final adjustments for alignment and ensure the actuator sits securely within the brackets.

5. Secure the Actuator

For foot mounts and other stationary mounts, tighten the bolts or screws that secure the actuator directly to the mounting surface. Double-check all connections and ensure everything is secure and stable.

6. Connect Electrical Components (if applicable):

If you’re using a motorized actuator, carefully connect the electrical wires according to the manufacturer’s instructions. Double-check all connections for proper polarity and ensure they are safe and secure.

7. Test and Verify

Before applying any load, power on the actuator and observe its movement. Check for any abnormal sounds, vibrations, or binding.

If using a clevis mount, ensure the pin is properly seated and the actuator moves freely within the brackets.

Once satisfied with the operation, you can proceed to apply the intended load and operate the actuator as required.

Maximizing Mounting Efficiency

Once you’ve chosen your mounting method, meticulous installation is crucial for optimal performance. Here are some key tips for maximizing mounting efficiency:

- High-Quality Hardware: Invest in robust bolts, screws, and other hardware that can withstand the anticipated load and environmental conditions.

- Precise Alignment: Ensure the actuator is mounted straight and level to avoid binding and premature wear.

- Secure Tightening: Loose hardware can lead to vibrations and noise, impacting performance and longevity.

- Follow Instructions: Each actuator comes with specific mounting instructions. Carefully follow them for a successful installation.

Regular maintenance, including checking the tightness of connections and inspecting for wear and tear, is essential for ensuring optimal performance and the long life of your linear actuator.

If you encounter any challenges during the installation process, consult a qualified technician for assistance.

Maxim Systems: Your Partner in Linear Actuator Solutions

At Maxim Systems, we’re your trusted partner in the world of linear actuators and mounting solutions. We offer a comprehensive range of actuators and mounting accessories, catering to diverse applications. Our team of experts is here to assist you in selecting the right products and providing technical support throughout your project.

Contact us today and unlock the full potential of your linear actuators!