Rotary indexing tables are widely used in Automotive Manufacturing. Electronics Production. Medical Device Fabrication, Food and Beverage Packaging, and Aerospace Component Manufacturing industries. In this article, we will discuss everything about What is a rotary indexing table and how does work it.

What is a Rotary Indexing Table?

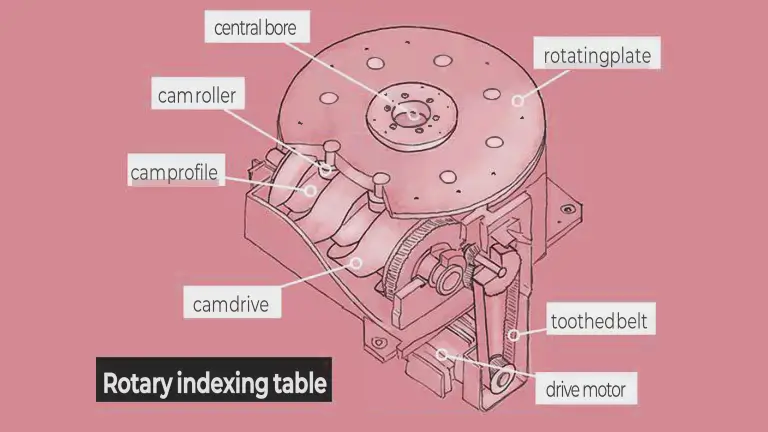

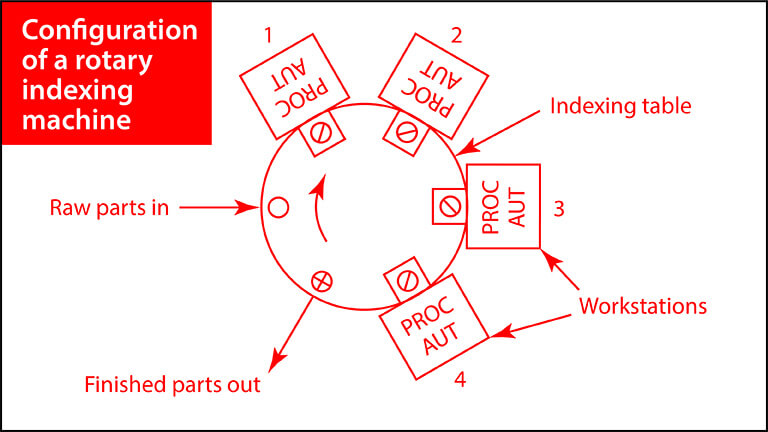

A rotary indexing table is a mechanical device used mainly in manufacturing and automation to facilitate the sequential processing of workpieces. It typically consists of a circular platform with multiple workstations positioned around its perimeter.

The main function of a rotary indexing table is to rotate incrementally, bringing each workstation into position for the assigned task. At each workstation, specific manufacturing operations such as drilling, milling, assembly, or inspection are performed on the workpiece as it progresses through the production process.

Features of Rotary Indexing Table

Rotary Indexing Tables have Multiple Workstations Equipped with several stations around its borders. It moves stepwise to align workpieces accurately at each station for efficient handling and helps with various tasks like drilling, milling, and assembly.

Easy Customization

Adapting to diverse production needs. You can easily customize its size, station count, and configuration to fit specific manufacturing requirements.

Built Materials

Rotary indexing tables are built from durable materials for longevity and reliability in industrial settings, which enable the optimization of workstation activities for maximum productivity through advanced control mechanisms.

It helps in areas where material loading and unloading is concerned, further improving workflow efficiency. It incorporates emergency stop buttons and protective guards to prioritize operator safety in manufacturing environments.

Types of Rotary Indexing Tables

There are several types of Rotary indexing tables such as

- Fixed Indexing Tables

- Servo Indexing Tables

- Cam Indexing Tables

- Direct Drive Indexing Tables

- Precision Indexing Tables

- Multi-Station Indexing Tables

Each type of rotary indexing table offers unique advantages and is suited to different manufacturing requirements and preferences. Here are some common types of rotary indexing tables:

Fixed Indexing Tables

Fixed indexing tables have a fixed number of stations evenly distributed around the table’s border. They rotate in fixed increments, typically stopping at each station for a set amount of time.

Servo Indexing Tables

Servo indexing tables are different from fixed indexing tables, they offer more flexibility in rotational speed and positioning. They use servo motors for precise control over rotation, allowing for variable indexing speeds and customizable positioning.

Cam Indexing Tables

Cam indexing tables use a cam mechanism to control the rotational movement. The cam profile determines the indexing pattern, enabling precise and repeatable positioning of workpieces at each station.

Direct Drive Indexing Tables

These tables feature a direct drive mechanism, where the rotary motion is generated directly without the need for gears or other transmission components. This results in smoother operation, higher accuracy, and reduced maintenance requirements.

Precision Indexing Tables

Precision indexing tables are designed for applications that require extremely accurate positioning and repeatability. They often incorporate high-precision bearings and drive systems to achieve tight tolerances and minimal positional errors.

Multi-Station Indexing Tables

Multi-station indexing tables have a larger number of stations compared to standard indexing tables. They are used for complex manufacturing processes that involve multiple operations or require high production throughout.

How Does A Rotary Indexing Table Work?

Rotary indexing tables do a simple but important job. Here’s how does a rotary indexing table work:

- Workpiece Loading: The operator puts the workpieces on the table’s workstations and makes sure they are securely held in place.

- Indexing: The table turns to the right position and lines up with other machines. This can be done manually, with air pressure, or using motors, depending on the table’s design.

- Processing: At each workstation, the machines do their tasks. This could be inserting parts, joining pieces, fastening, checking quality, drilling, milling, or welding.

- Repeat Indexing: After finishing the tasks at one station, the table turns to the next position. This keeps going until all the stations have been used.

- Unloading: Once all the tasks are done, the operator takes the finished workpieces off the table. Sometimes, robots, air pushers, or chutes automatically unload the workpieces.

Rotary indexing tables are precise and repeatable, making sure workpieces are correctly positioned for each task. This leads to high-quality products and consistent results quickly and efficiently.

Benefits of Rotary Indexing Tables

Rotary indexing tables are precise and repeatable, making sure workpieces are correctly positioned for each task. This leads to high-quality products and consistent results quickly and efficiently.

- Multiple tasks happen at the same time, speeding up production.

- Ensures accurate positioning, leading to high-quality results.

- Combines many workstations into one compact unit.

- Automates tasks, cutting down on manual labor.

- Can be customized for different jobs like drilling, milling, or assembly.

- Handles many workpieces at once, increasing output.

- Works well with other automated systems like robots.

- Made from strong materials for long-lasting use.

- Includes safety features like emergency stop buttons and guards.

- Improves efficiency and consistency, saving money over time.

Industries That Uses Rotary Indexing Tables

Rotary indexing tables are widely used in various industries due to their ability to enhance productivity, precision, and efficiency in manufacturing processes. Here are some key industries that benefit from rotary indexing tables:

- Automotive: Used for tasks like engine assembly, transmission machining, and chassis welding.

- Electronics: Essential for PCB assembly, component soldering, and device testing.

- Medical Devices: Helps in the precise manufacturing of surgical instruments, implants, and diagnostic equipment.

- Consumer Goods: Used in the production of furniture, appliances, and toys for tasks like drilling, assembling, and packaging.

- Food and Beverage: Facilitates automated filling, sealing, labeling, and packaging of products.

- Aerospace: Employed for machining and assembling aircraft parts and components.

- Tool and Die Making: Used for creating molds, dies, and tooling components with high precision.

- Pharmaceuticals: Assists in the production and packaging of medications and medical products.

By integrating rotary indexing tables into their production lines, these industries can achieve higher output, consistent quality, and reduced labor costs, making them an invaluable asset in modern manufacturing.

Selecting The Right Rotary Indexing Tables For Your Application

Choosing the right rotary indexing table involves understanding your specific manufacturing needs and matching them with the right features. Consider the following factors when selecting a Rotary indexing table that enhances your production efficiency and meets your operational goals:

- Load Capacity

- Number of stations

- Precision

- Speed

- Drive type

- Control system

- Durability

- Customizability

- Space

- Budget

Conclusion

Rotary indexing tables are essential tools in modern manufacturing, offering efficiency, precision, and versatility. They enable simultaneous operations on multiple workpieces, reduce manual labor, and ensure consistent quality. By understanding how these tables work and their benefits, manufacturers can enhance their production processes, achieve higher throughput, and maintain stringent quality standards.