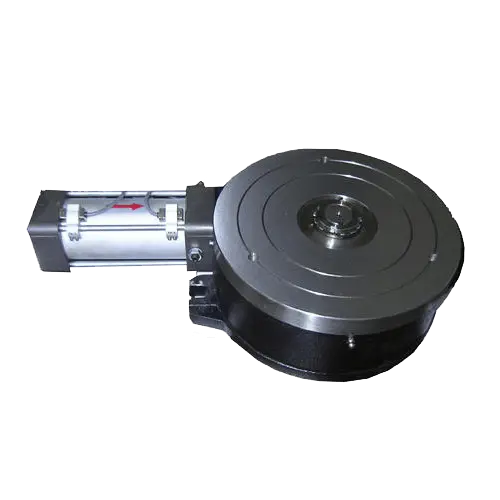

Maxim Systems, a rotary indexing table supplier who provides Rotary Indexing Table designed to increase your automation performance with accuracy and reliability. These tables are ideal for a variety of industrial applications, including assembly lines, manufacturing machines, and analytical systems.

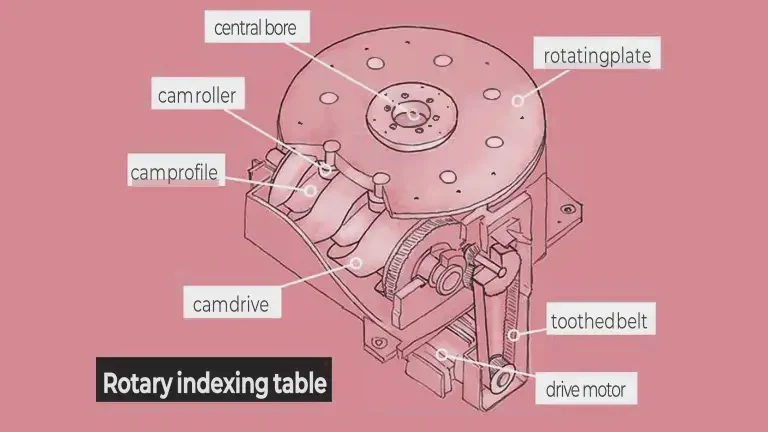

A rotary indexing table is a device that rotates items to specific, equal positions or stations in a circular pattern. This precision mechanism is often used in manufacturing and assembly lines to perform tasks like machining, inspection, or assembly at each station.

At Maxim Systems we offer a range of rotary indexing tables to for your different requirements:

Rotary indexing tables operate by rotating a platform (the table) to predefined positions or angles. Here’s a simplified explanation of their working principle:

Rotary indexing tables are versatile and used in various industries, including:

Selecting the appropriate rotary indexing table is crucial for ensuring optimal performance and reliability. Here are the key factors to consider:

Select The Type

By identifying the type of rotary indexing table that best suits your application, you can ensure efficiency, precision, and longevity in your operations.

Drive Mechanism

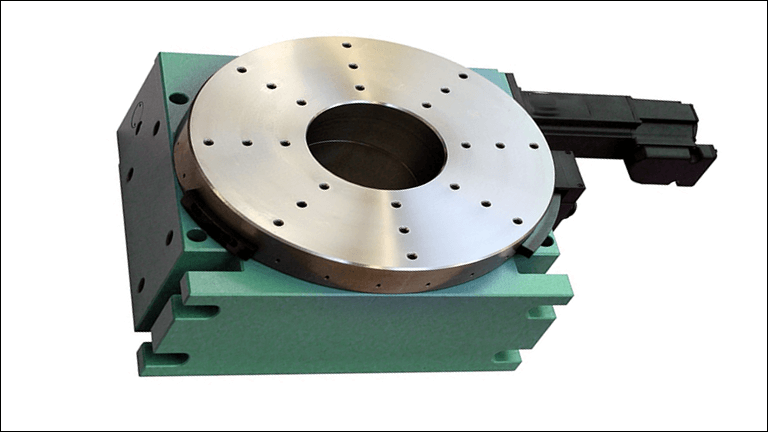

Load Capacity and Size

Ensure the table supports the weight and size of your workpieces. Heavy-duty tables are necessary for larger components, while lighter models suffice for smaller items.

Indexing Precision and Speed

Choose based on the required precision and speed. Servo-driven tables generally provide the highest precision.

Environmental Conditions

Consider exposure to dust, moisture, or extreme temperatures. Choose tables with appropriate protection for such environments.

At Maxim Systems, we pride ourselves on providing high-quality rotary indexing tables that enhance the efficiency and precision of your industrial operations. Here’s why you should choose Maxim Systems as your rotary indexing tables supplier:

Wide Range of Products: We offer a comprehensive selection of rotary indexing tables, including fixed station, flexible, and heavy-duty options, to meet diverse application needs.

Precision Engineering: Our tables are designed with precision and reliability in mind, ensuring accurate and repeatable positioning for your tasks.

Custom Solutions: We provide tailored solutions to fit your specific requirements, whether it’s for automotive assembly, electronics manufacturing, or heavy machinery operations.

High-Quality Components: Our rotary indexing tables are built with top-quality materials and components, such as cam rollers, drive motors, and toothed belts, to ensure durability and long-term performance.

Expert Support: Our team of experts is available to assist you from selection to installation and maintenance, ensuring you get the most out of your investment.

Alkon Corporation: Alkon Corporation is a leading manufacturer of high-quality rotary index tables. The company’s products are known for their precision, durability, and compatibility with different manufacturing applications.

The rotary indexing table is an essential component in modern industrial automation, offering precise, reliable, and programmable solutions for various manufacturing and assembly tasks.

At Maxim Systems, we provide a comprehensive range of rotary indexing tables designed to meet the specific demands of different industries, from automotive to aerospace. With our commitment to quality, precision engineering, and expert support.

Contact us to enhance the efficiency and accuracy of your operations.

Maxim Systems is dedicated to offering the finest pneumatic components and related services available.

© Copyright 2023 by Maxim Systems, INC. Designed And Developed By P Cube Digital

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |