- Home

- Products

- Manufacturers

- ACE

- Accu Tech USA

- Adsens Technology

- Alkon Corporation

- Apex Dynamics

- ATP

- Belden

- Canfield Connector

- Contrinex

- Daughtridge Sales

- Edco USA

- Enfield Technologies

- Fabco-Air

- Helukabel

- HIWIN

- Hofmann Fluid Power

- HTM Sensors

- IAI

- JVL International

- Lutze

- Mencom

- Midland Industries

- Moteck

- Master Pneumatic

- NGT Valves

- Master Pneumatic

- Murrelektronik

- Nason

- OTP

- Pilz

- PMI Group

- Pneumatic Cylinders & Couplers

- Prevost

- RUB Valves

- Saginaw Control

- Schmalz

- Sheffer Corporation

- SMC

- STC Valve

- Timotion

- Tolomatic

- Universal Components

- Wire Crafters

- Yates Industries

- Zero Max

- Metal Finishing

- Machining

- About Us

24/7 Custom Support

540-265-9050

Reach Us RIght Away

cs@maximsystems.net/

Chat Now

cs@maximsystems.net/

Latest Updates

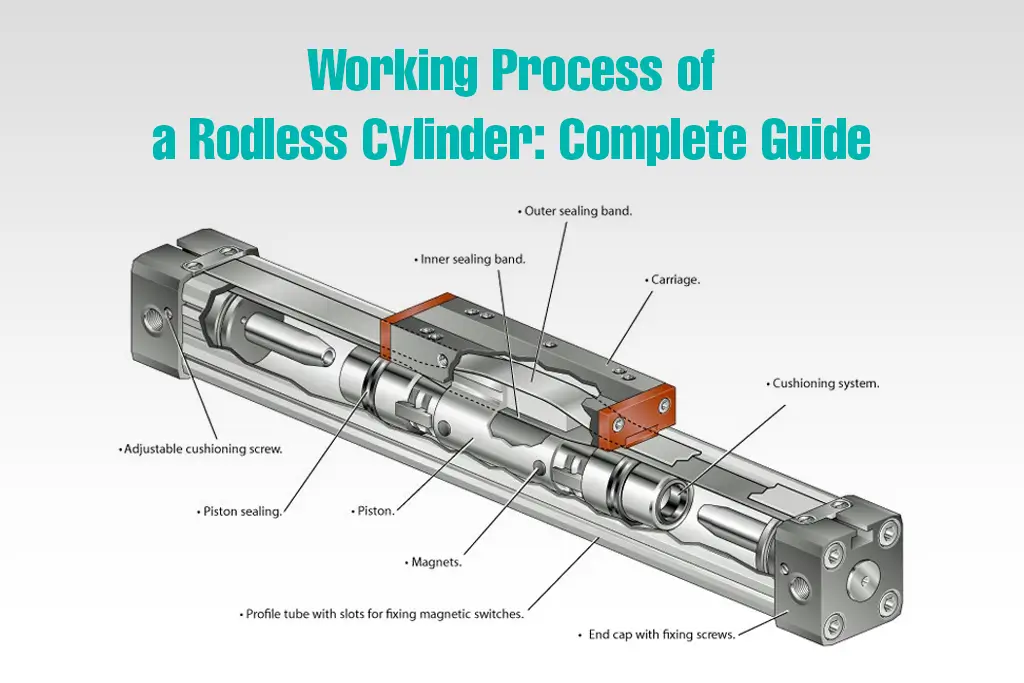

A rodless cylinder is a type of pneumatic cylinder that operates without an….

Rotary indexing tables are widely used in Automotive Manufacturing. Electronics Production. Medical Device….

Ever found yourself locked out of your own home with no spare key….

Quick Connect