How to Fix a Stuck Solenoid Valve (Step-By-Step Guide)

Having trouble with your sprinklers? It might be a faulty solenoid valve. Here’s a simple guide on how to fix a stuck solenoid valve. If you’re not comfortable with any of these steps, call a qualified technician.

Electrical Issues

Check the Fuse: Locate the fuse box on your irrigation controller. Consult the manual to identify the correct fuse for the solenoid valves.

Replace the Fuse: If the fuse is blown, replace it with a fuse of the same amperage rating. Never use a higher amperage fuse. Blown fuses can happen if the valves were wired incorrectly in the past.

Wiring Check

Turn Off Power: Before touching any wires, make sure the power to your irrigation controller is completely off.

Match the Wires: Each solenoid valve should have two wires connected to the coil. Follow these wires back to the irrigation controller.

Common Terminal: One wire should be connected to the “common” terminal on the controller. This terminal is usually labeled clearly in the manual or on the controller itself.

Station Terminal: The other wire should be connected to the specific “station” terminal on the controller that corresponds to the valve you’re checking. For example, if the valve controls Zone 3, the wire should be connected to the “Station 3” terminal.

Secure Connections: Make sure all the wire connections are tight and secure. Loose or corroded connections can also cause problems.

Valve Issues

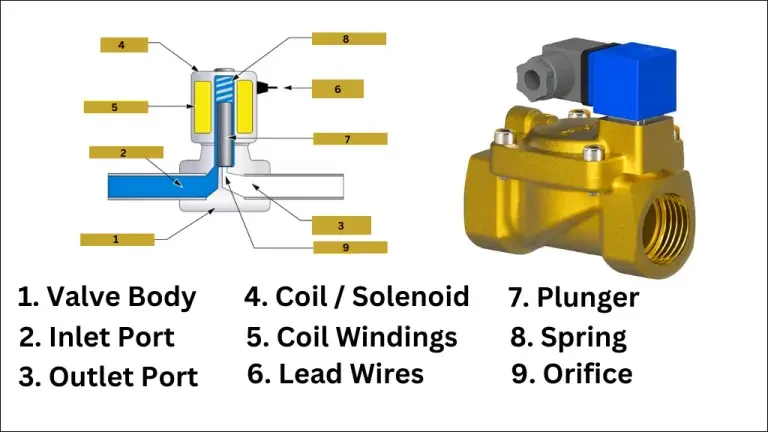

Flow Control Stem. Locate the flow control stem on the solenoid valve. It’s usually a knob or screw-like adjustment on the valve body.

Open the Stem. Turn the flow control stem fully counter-clockwise to open it completely. This will allow for maximum water flow through the valve.

Wrong Direction?

Flow Arrow. Double-check the direction of the valve. There should be an arrow clearly marked on the valve body indicating the direction of water flow.

Match the Arrow. Make sure the arrow points in the same direction as the water flow in your system. If the valve is installed backwards, it won’t open properly.

Manual Switch Check

Locate the Switch: Some solenoid valves have a small manual switch near the coil. This switch allows you to open the valve manually for testing or flushing purposes.

Switch Position. In most cases, the manual switch should be in the “OFF” position. If the switch is in the “ON” position, the valve will stay open even when the controller isn’t sending a signal, allowing water to flow through it even if other valves are not activated.

Solenoid Coil Issues

Turn Off Power. Before working on the coil, make sure the power to your irrigation controller is completely off.

Unscrew the Coil. Carefully unscrew the coil from the valve body.

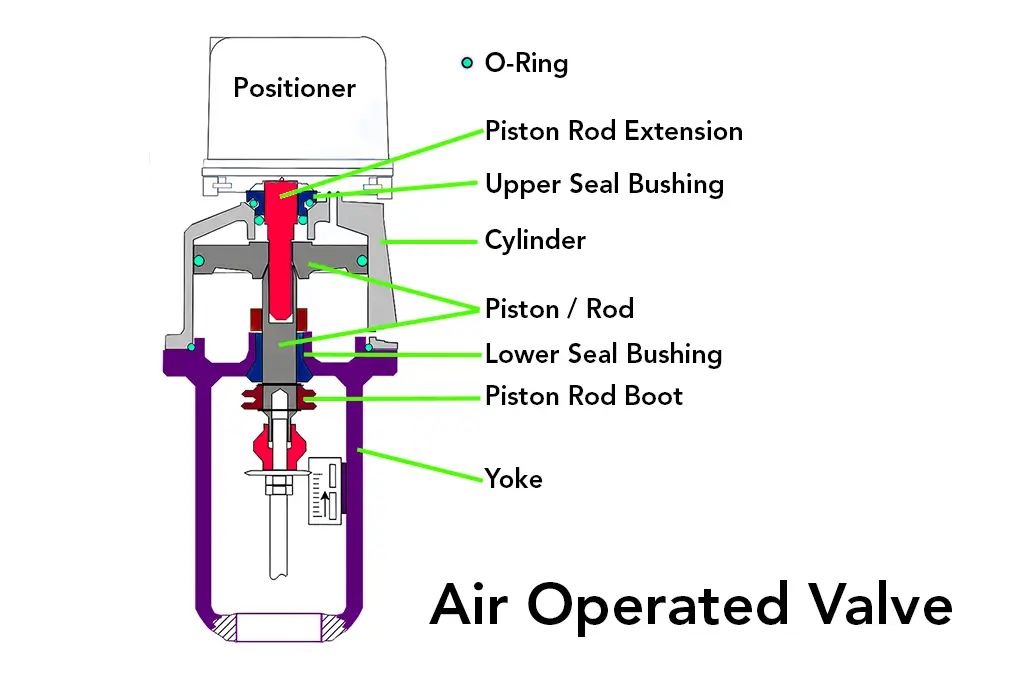

Check the O-ring. Look for a small rubber ring (o-ring) where the coil meets the valve body. This o-ring creates a watertight seal.

Replace the O-ring. If the o-ring is missing, damaged, or cracked, replace it with a new one of the same size.

Stuck Plunger

Unscrew the Coil (see Missing O-Ring above). Follow the steps above to remove the coil.

Locate the Plunger. Inside the coil, you should see a small metal rod called a plunger.

Test the Plunger. The plunger should move freely up and down when you press it gently with your finger. If it’s stuck, it won’t allow the valve to open properly.

Clean the Plunger. If the plunger is stuck, carefully remove it and clean it with clean water. Do not use any lubricant, as this can attract dirt and cause further problems.

Reassemble Carefully. Once cleaned, carefully reinsert the plunger back into the coil and screw the coil back onto the valve body.